Laser and Plasma Cutting at Mascot Steel

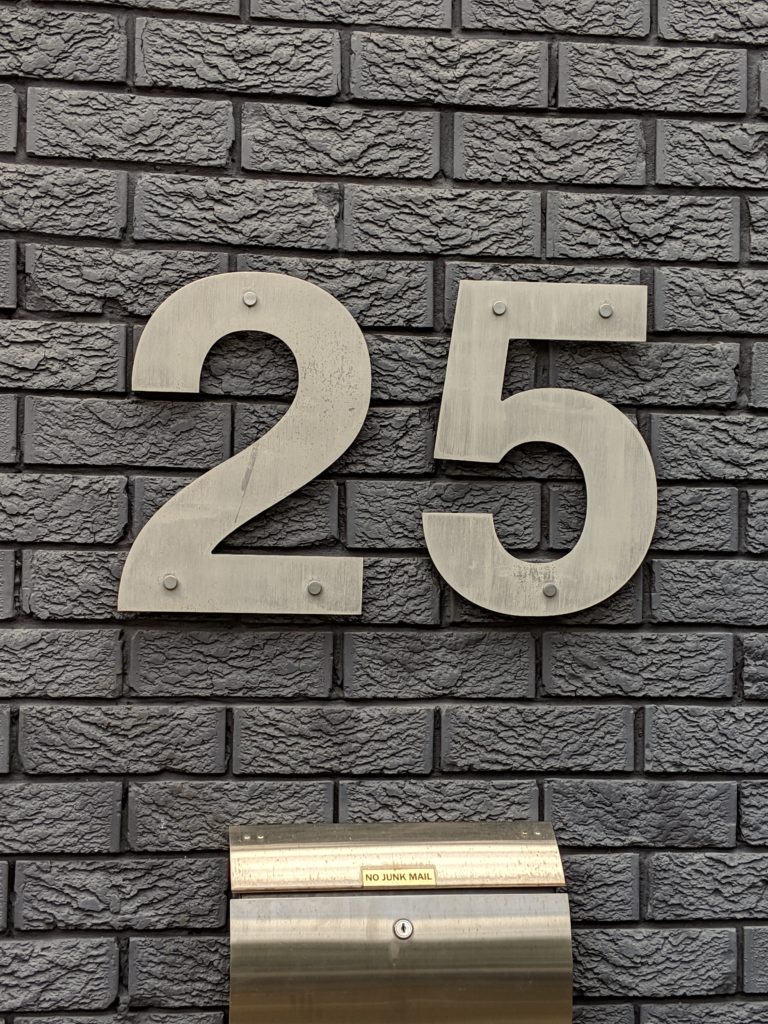

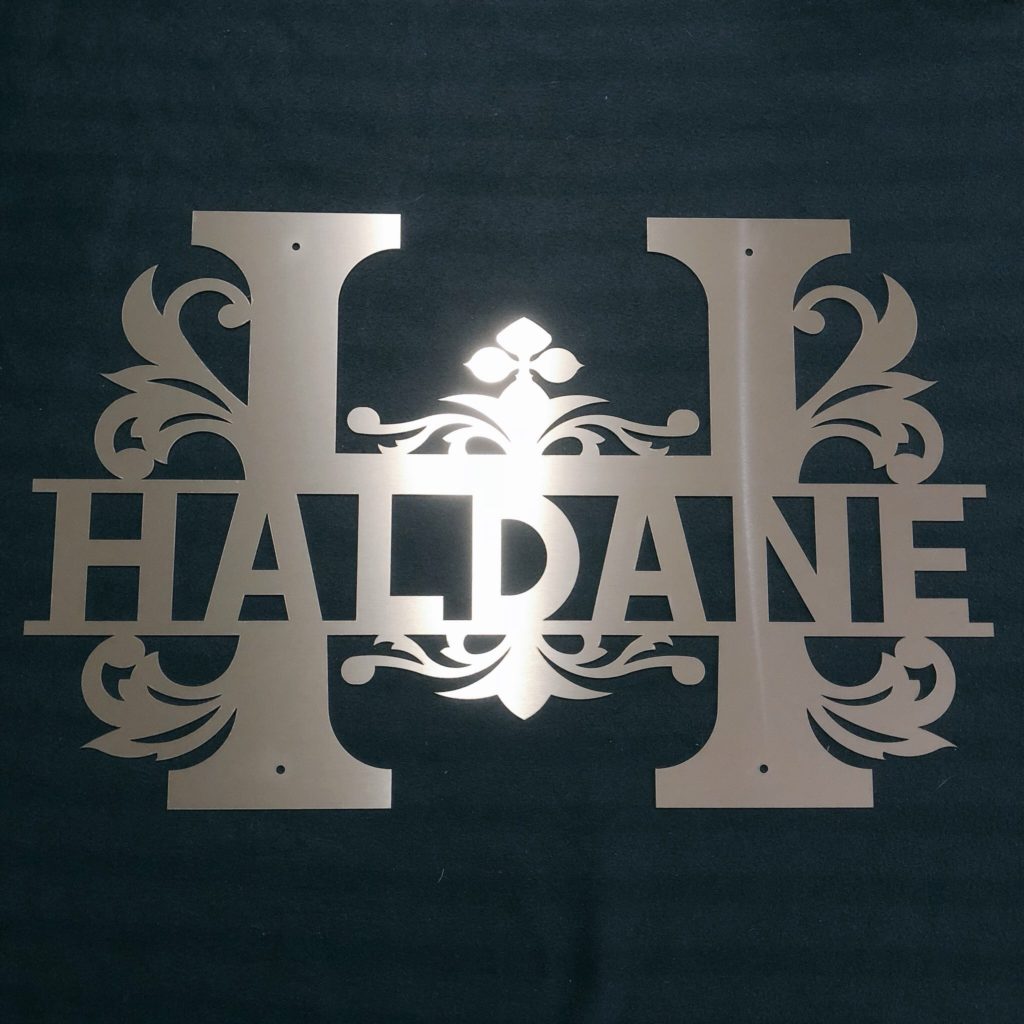

Check out some photos from our latest work using plasma and laser cutting machines! Our experienced sales team can work with you to bring your intricate drawings to life and advise you on the best materials. Our team at Mascot Steel use the latest software to cut metal with quick turnarounds and outstanding results. Call us today to get your job done 02 9313 1313.

Plasma cutting is a process that cuts through steel by means of an accelerated jet of hot plasma. Due to the high speed and precision cuts combined with low cost, plasma cutting sees widespread use from large-scale construction applications down to small DIY jobs.

Laser cutting is a technology that uses a laser to cut materials and is typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. The focused laser beam is directed at the steel, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.